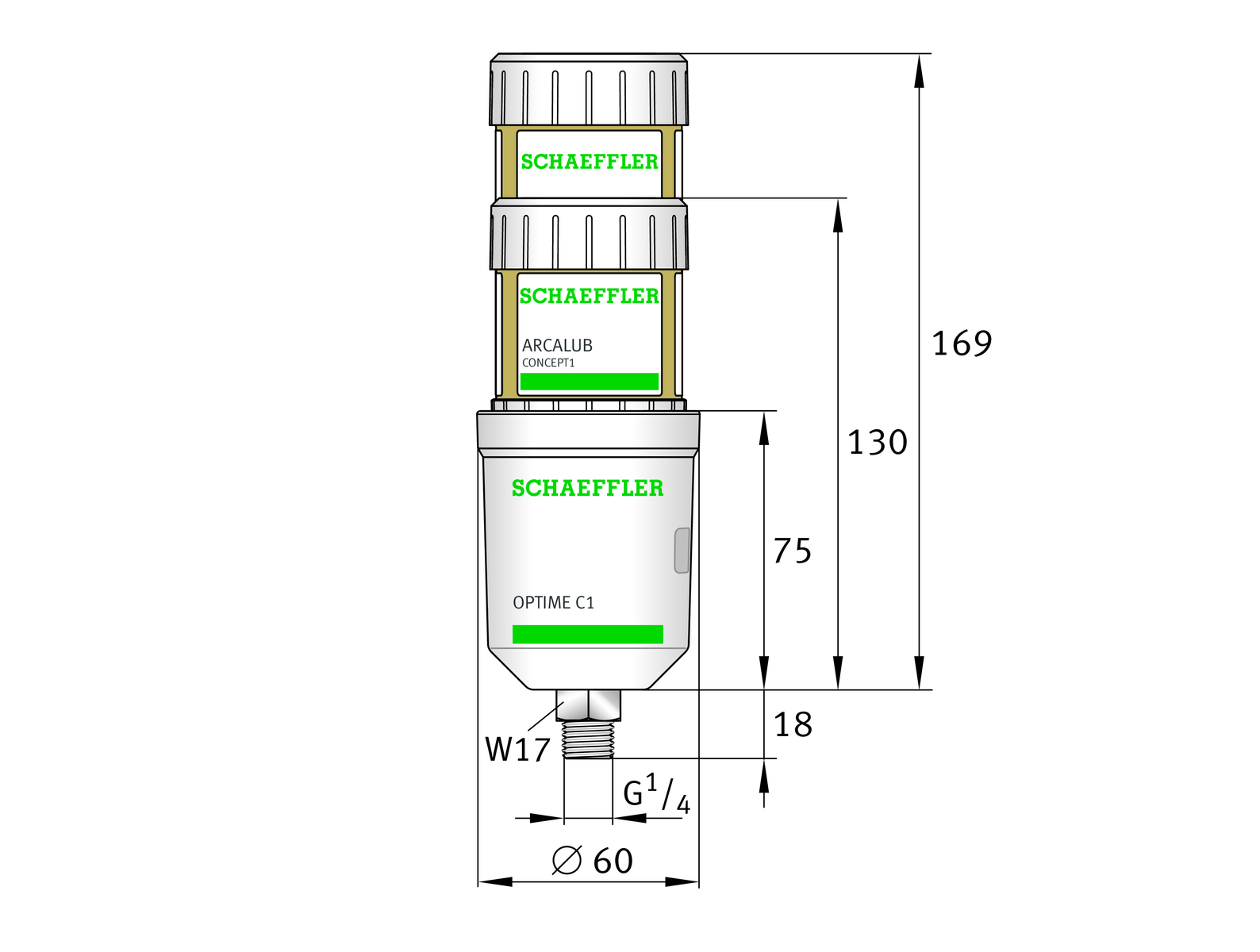

The World’s First Smart Lubricator - Optime C1

Manual relubrication of rolling bearings is still the norm in many areas of industry. Automatic greasers are a big improvement in this regard, but they still require manual supervision. Generally speaking, manual relubrication mistakes are one of the main causes of rolling bearing failure. The bearing specialists at Schaeffler have solved this problem. They have developed OPTIME C1 - rolling bearing relubrication solution using intelligent automatic greasers. The new system integrates with Schaeffler's OPTIME app to reliably prevent incorrect lubrication due to using too much or too little grease, using the wrong grease, grease contamination, blocked bearing lubrication channels or empty grease nipples.

The system communicates with the maintenance staff through the application OPTIME, the web-based dashboard of OPTIME if necessary through their proprietary software tool, giving them an overview of all grease nipples that have critical fill levels or lubricant delivery issues. Thanks to its built-in temperature sensor, the system also provides an overview of all grease guns that operate at elevated temperatures. With OPTIME C1, maintenance personnel no longer have to spend time on scheduled inspections or deal with complex spreadsheets or software to schedule relubrication in their plants. Instead, they can focus on targeted maintenance activities in response to automated notifications from the app. This takes a lot of the complexity out of lubrication management.

Simple and upgradeable: a system solution consisting of only a few components. Each module OPTIME C1, battery powered, designed to screw onto an automated greaser Schaeffler Concept 1. The device includes a communication module and a temperature sensor. The appliances OPTIME C1 automatically connect the Concept 1 greasers to form a network connection. The network connection captures and calculates key operational data, such as the number of days until the next lube refill, and sends it through the gateway to the cloud at Schaeffler and then to the application OPTIME. It takes less than two minutes per grease point to install the components and configure them in the application. Thus dozens of lubrication points for pumps, fans, compressors, machines, conveyor drives and the like can be fitted with OPTIME C1 for a very short time - meaning they can be removed from the manual review schedule. The greasers at these points are now intelligent, meaning that the maintenance team only needs to attend to them when they actually need maintenance.